Who We Are

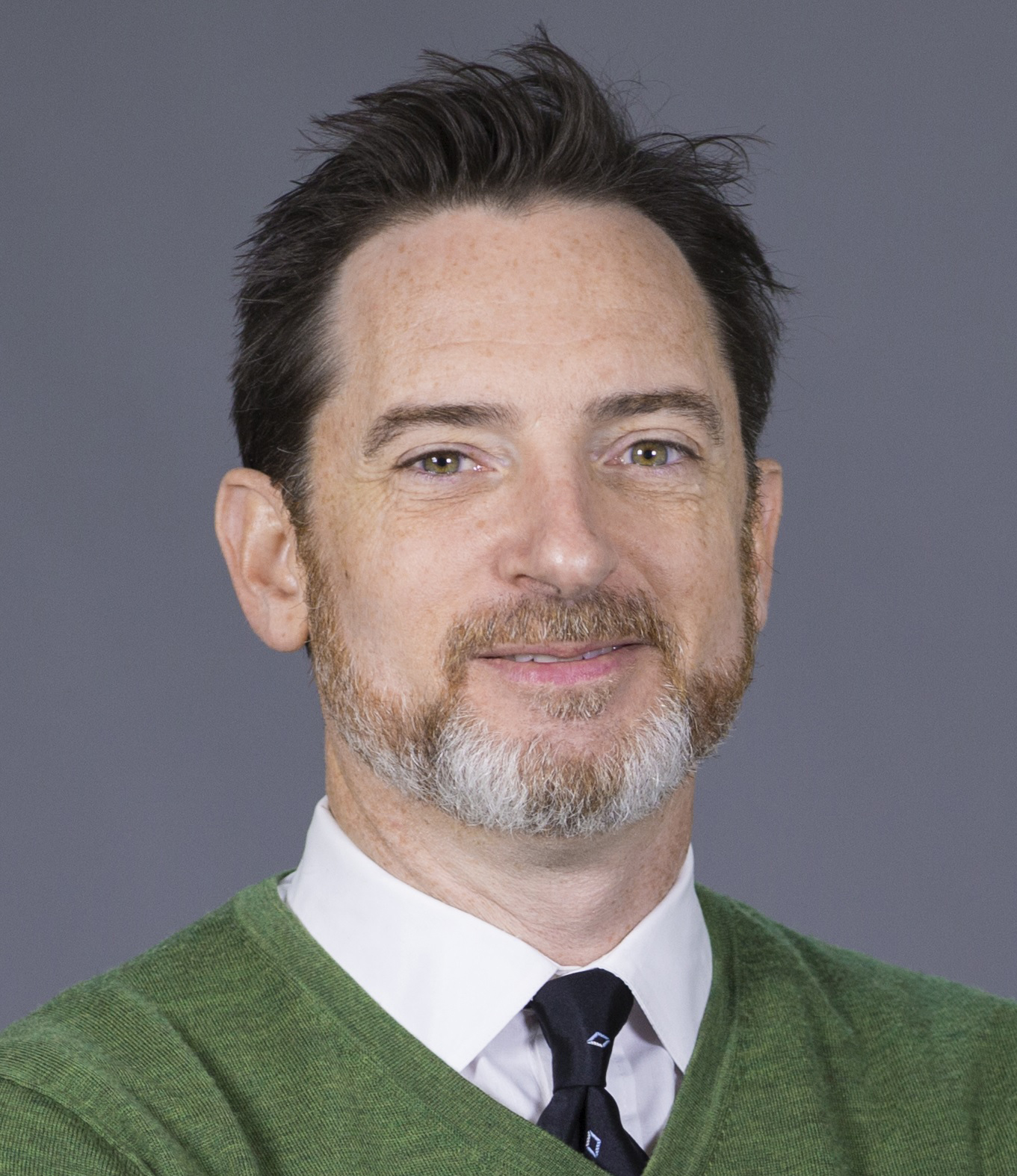

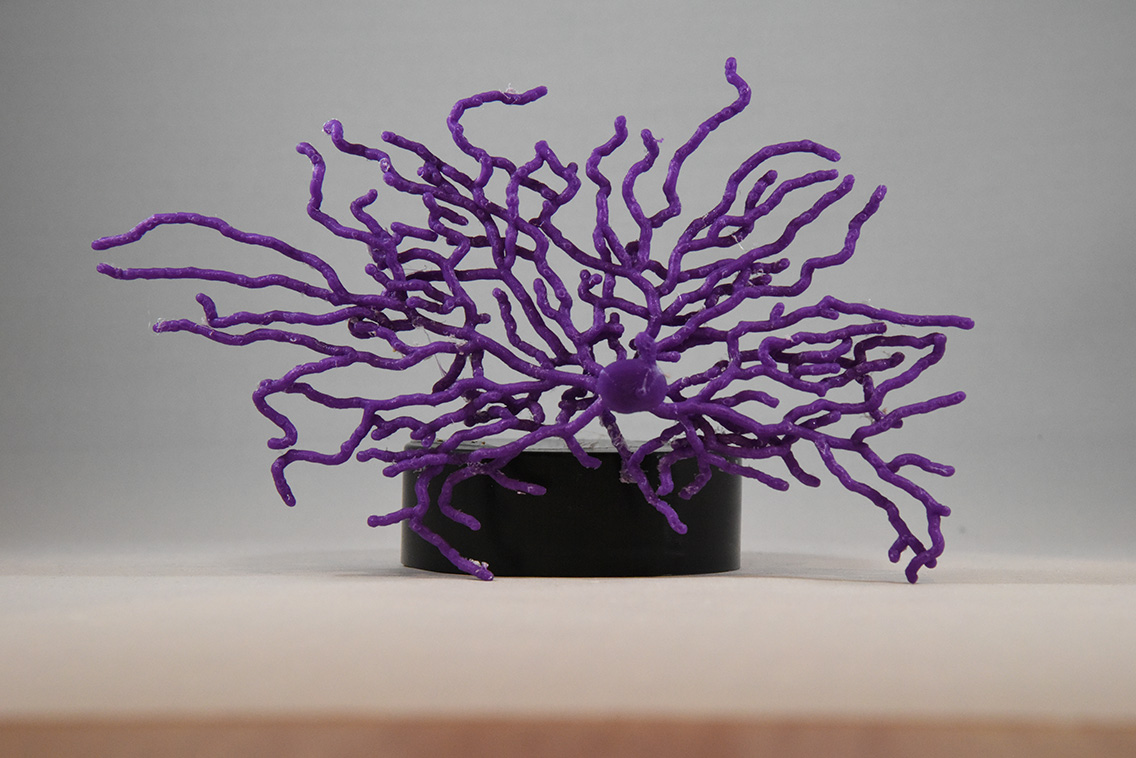

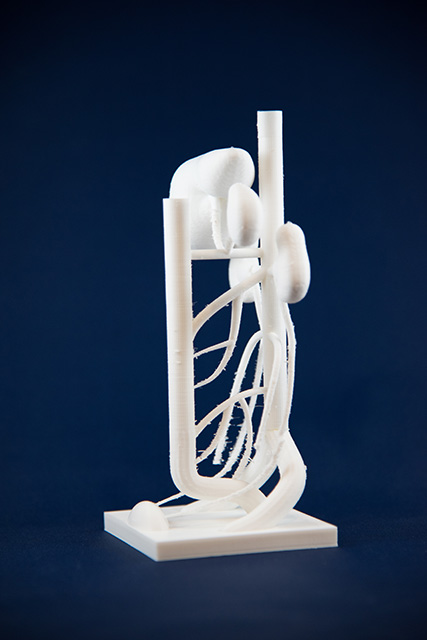

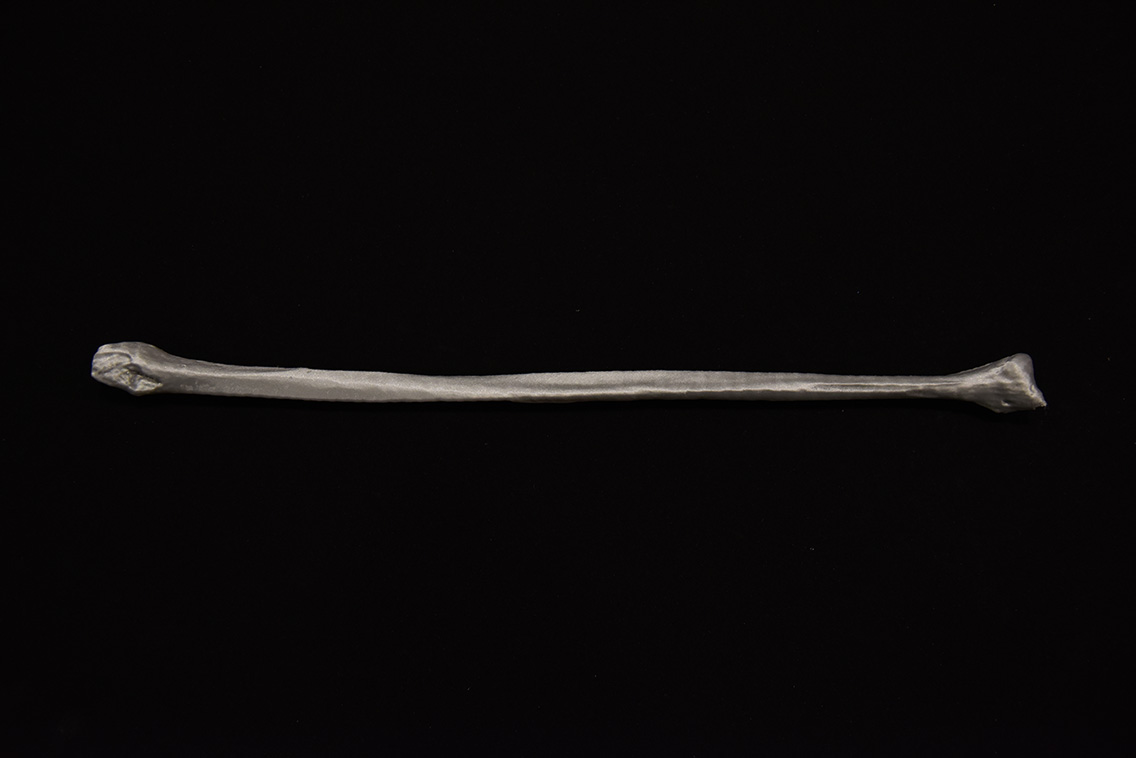

The NYU Health Sciences Library’s 3D Printing and Prototyping Service collaboratively supports the NYU Langone Health community by providing the tools, equipment, and knowledge needed to transform ideas into tangible forms.

What We Offer

- Project consultation

- No fee printing and materials

- High quality results

- Clear, consistent, and responsive communication

- Supported exploration of 3D and Makerspace technologies

If you encounter any issues using our request form

please email us at #HSL_3DPP@nyulangone.org

Please submit questions related to 3D Printing & Prototyping using this form. The 3D Printing & Prototyping Team will contact you to discuss any issues or concerns about your proposed project within one to three business days, as well as discuss your timeline and options. We will also give you a projected time line for any processes, orders, or prints.

| Printing Requests | ||

|---|---|---|

| If your request(s) requires... | ...expect those to be ready for pick up within | Examples |

| Up to 500 grams of material | 1 to 2 weeks | A pen holder, toy car, face shield visor, etc. |

| Up to 1000 grams of material | 2 to 3 weeks | A to-scale human skull, human brain, etc. |

| More than 1000 grams of material | 3 to 4 weeks | A pediatric hollow torso, a 1 gallon container, etc. |

| ** Please note, requests for prints consisting of more than 1000 grams of material may be subject to further discussion concerning material acquisition from one's department. | ||

Frequently Asked Questions about 3D Printing

What is 3D printing?

3D printing is a way of manufacturing prototypes and physical models by adding material as opposed to removing it. There are a variety of 3D printing methods in existence. The Health Sciences Library offers Fused Deposition Modeling (FDM), Stereolithography (SLA) and PolyJet printing. We can work with you to determine which method best fits your need.

What 3D printing services do you offer?

We offer design consultations, basic 3D model editing, and 3D printing on our Ultimaker S5, Form Labs 2 and Stratasys J5 printers.

How do I get something 3D printed?

You can fill out our 3D Project Request form or contact us at #HSL_3DPP@nyulangone.org

Can you help me design a 3D model?

Yes. In addition, we can help edit an existing model and recommend resources for performing various modifications.

How much does 3D printing cost?

Currently all of our 3D printing services are offered at no cost.

How long does it take?

Preparing for the print can take a few days. Furthermore, the printing process itself may take up to a week. A good rule of thumb would be a one- to two-week turnaround time.

What materials and colors do you have available?

You can find a list of materials here. We will contact you with color options for your model.

Are there any limitations/prohibitions on what can be 3D printed by the NYU Health Sciences Library?

All items submitted as part of the 3D Printing request need to be related to medical education or research in some way or format. Furthermore, the requestor must have permission to use the 3D model provided. Finally, we offer our services as is and provide no warranties or guarantees.

Learn More About 3D Design

Free Downloadable Models

- NIH 3D Print Exchange

- Embodi3D

- Thingiverse

- 3D Warehouse

- yeggi

- Repables

- Smithsonian

- Lawrence University Chemistry Dept. 3-D Printable Objects

Free 3D Design Resources

Convert DICOM to 3D Printable Models

Our Equipment and Software

What is 3D Printing?

Information about 3D Printing Materials

We offer a wide variety of 3D printing materials depending on the printer you've chosen and your intended application. Please refer to the chart below and follow the links to the manufacturers' websites, or contact us for more information.

| Ultimaker | ||

|---|---|---|

| Material | Properties | Uses |

| PLA | Odorless, low-warp, eco-friendly, less energy to process | Ideal for models and prototypes that require aesthetic detail |

| Tough PLA | Impact strength similar to ABS, greater than regular PLA; higher stiffness compared with ABS; less brittle than regular PLA | Ideal for reliably printing functional prototypes and tooling at larger sizes |

| CPE+ | Chemical resistant, tough and demonstrates good dimensional stability, higher temperature resistance and increased impact strength | Ideal for models and prototypes that require aesthetic detail |

| TPU | Flexible 3D printing material, excellent abrasion resistance, smooth feeding properties, durable | Go-to choice for a wide array of manufacturing projects that demand the qualities of both rubber and plastic |

| ABS | Makes durable parts that need to withstand higher temperatures, easy to print with, strong plastic | Allows the creation of functional prototypes and complex end-use parts |

| PVA | Non harmful, non-toxic, and environment friendly, easily dissolved in water under normal temperature, easy stripping | Ideal for printing complex models that require supports for large overhangs, deep internal cavities, and intricate geometries |

| Nylon | Strong, lightweight, durable, flexible, wear-resistant, 100% thermoplastic | Great choice for 3D printing tools, functional prototypes, and end-use parts |

| Form Labs | ||

| Material | Properties | Uses |

| Clear Resin | Polishes to near optical transparency, making it ideal for working with light or showcasing internal features. Supports print resolutions: 100, 50, and 25 microns | Great for fluidics and moldmaking, optics, lighting, and any parts requiring translucency |

| Tough 2000 Resin | Simulates the strength and stiffness of ABS | Strong and sturdy parts that should not bend easily and require minimal deflection |

| Surgical Guide Resin | Autoclavable, biocompatible | To meet solvent disinfection and autoclave sterilization standards |

| Stratasys | ||

| Material | Properties | Uses |

| Vero | Multi-color, excellent detail visualization with strength | Smooth, accurate prototypes, anatomical models, moving and assembled parts |

| Elastico | Rubber-like, durable, tear-resistant, can stand up to repeated flexing and bending | Anatomical models, end-use parts |

| Vero Ultra Clear | Simulates acrylic, achieving 95% light transmission of that material | Models that need to show internal parts |

Copyright

3D designs, including designs you create, are subject to intellectual property rights including copyright. You are required to investigate and follow the licenses accompanying 3D designs that you ask the NYU Health Sciences Library to print on your behalf. We reserve the right to request information related to the licensing of a design, and refuse any print job where we believe we would infringe on someone's intellectual property.